Polyethylene foam is a type of plastic material that is produced in the form of cells or foam. Polyethylene is a polymer made from repeating units of ethylene. Polyethylene foam uses foaming agents to trap air or other gases in its cell structure, which creates a light and strong structure.

Due to properties such as lightness, thermal insulation, sound insulation, flexibility and resistance to shocks, polyethylene foam is used in various industries such as packaging, automotive, furniture, electronics, construction and sports industries.

Types of polyethylene foam:

Polyethylene foam is available in various forms in the market and it is available in different compositions and features. Some common types of polyethylene foam are:

1. Open polyethylene foam:

This type of polyethylene foam has an open cell structure where some cells are not connected to each other. This foam has lighter weight and less hardness and is used as thermal and sound insulation, packaging and industrial uses.

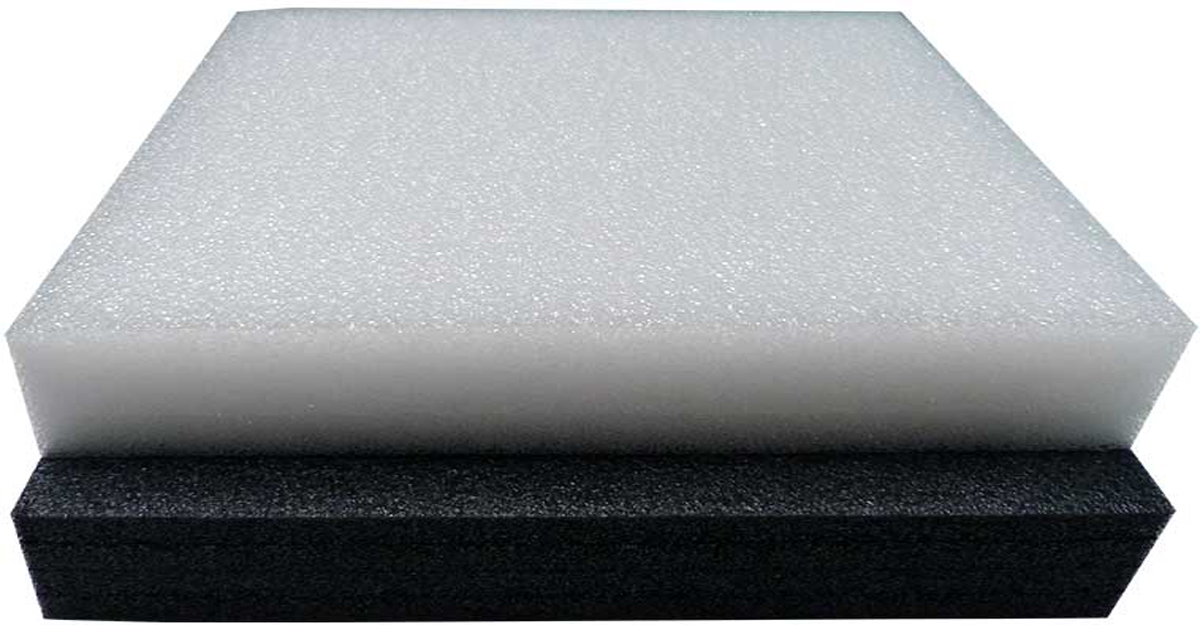

2. Closed polyethylene foam:

This type of polyethylene foam has a closed cell structure where the cells are connected to each other. This foam has higher resistance than open polyethylene foam and is used in packaging, transportation, and product protection industries.

3. Linear polyethylene foam:

This type of polyethylene foam has a linear cell structure and the cells are arranged in a chain along the length of the foam. This foam usually has high strength, flexibility and resistance to bending and is used in automotive, sports and furniture industries.

Also, different combinations and production methods can lead to the creation of other types of polyethylene foam that are used in different industries and uses.

Compositions of polyethylene foam:

Polyethylene foam is usually produced using various compounds and additives to achieve the desired properties for specific applications. Some common compounds and additives in polyethylene foam are:

1. Foam materials:

Foaming agents such as butane, pentane or dichlorofluoromethane (CFC) are used, which increase the volume of the cellulosic foam by producing vapor gases.

2. Filling materials:

To improve the mechanical properties of polyethylene foam and increase its resistance, fillers such as calcium carbonate, talc, gypsum and silica can be used.

3. Baking ingredients:

To control the curing process and foam formation, curing agents such as ammonium peroxide and hydrogen peroxide are used.

4. Stability additives:

Some additives such as thermal inhibitors and UV inhibitors are used to protect polyethylene foam from temperature changes and light radiation.

These compounds and additives can achieve special characteristics such as lightness, strength, insulation and resistance to heat and shock suitable for different needs of polyethylene foam by adjusting different amounts and ratios.